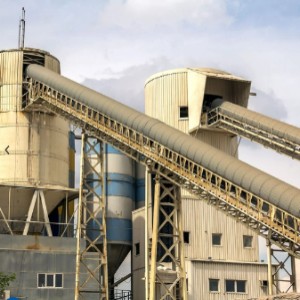

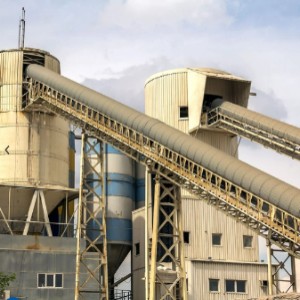

Predictive Maintenance and Monitoring for Conveyor Belts and Industrial Elevators

In modern industrial environments, conveyor belts and industrial elevators play a critical role in ensuring the efficient transport of materials, products, and components through various production stages. These systems are essential across multiple sectors, including:

🏭 Manufacturing

⛏️ Mining

🧊 Food processing

🚚 Logistics

📦 Industrial packaging

Despite their importance, the performance and reliability of these systems are frequently challenged by unplanned downtime, ineffective maintenance strategies, and safety risks.

Key Challenges in Conveyor and Elevator Systems

🔧 Unplanned Downtime

Unexpected failures in conveyor belts or industrial elevators can bring entire production lines to a standstill, resulting in costly delays and significant financial losses.

🛠️ Inefficient Maintenance

Conventional maintenance methods—either reactive or overly preventive—can lead to unnecessary costs, wasted resources, and lower system performance.

⚠️ Safety Hazards

Malfunctions in conveyor systems increase the risk of fire, mechanical failure, and falling debris, potentially causing serious workplace injuries and safety incidents.

To overcome common challenges like unplanned downtime, maintenance inefficiencies, and safety risks in conveyor belts and industrial elevators, El-Watch introduces the Neuron System—an innovative platform powered by wireless industrial sensors.

Among the most effective devices in the Neuron lineup are the Vibration RMS sensors, engineered for real-time monitoring and predictive maintenance in demanding industrial environments.

📡 Real-Time Monitoring with Neuron Vibration RMS Sensors

The Neuron Vibration RMS sensor continuously tracks key performance indicators such as temperature and vibration levels. This real-time data stream delivers a comprehensive view of the equipment's health, enabling early detection of anomalies and preventing unexpected failures.

🔧 Predictive Maintenance for Maximum Uptime

By analyzing historical and live sensor data, the system enables predictive maintenance strategies. This approach helps identify potential failures in advance, allowing for planned interventions before issues become critical—minimizing downtime and optimizing asset performance.

🚨 Instant Alerts for Fast Maintenance Response

The Neuron System is configured to issue instant alerts—via push notifications, SMS, or email—whenever abnormal conditions are detected. This allows maintenance teams to take rapid corrective actions, improving system reliability and workplace safety.